SideKick Tech

Manual

On the left you will find the most common problems that may arise

with your processor. Most are easily remedied. However, if you are not able to

troubleshoot your particular problem, call Phototherm Tech support, Monday-Friday, 8:00am

to 4:30 Pm EST (609) 396- 1456 or Fax (609) 396-9395. You can also Email us at serve@phototherm.com or go to our web sight, www.phototherm.com, and post a message on the message

board.

|

Under Developed Looking Slides

If your slides are coming out under developed or

"dark", either your temperature is to low or your first developer is weak or

diluted

1. Make sure that you are not "flooding" from the

processing drum. If during the process the drum starts leaking chemistry, causing it to

build up in the area underneath, a contamination is occurring in side the drum. One

chemical is being loaded on top the previous solution, causing the newly loaded chemical

to weaken . If this condition occurs, the processed film will almost always come out dark

or magenta.

Check to document on "Flooding at

Drum" to correct this problem

2. If you are not flooding, make sure the temperature is

correct in the heating chamber. Run a "Calibrate Temp" from

the unit

3. If your temperature is correct, remix first developer

Back

Leaking At Drum

Flooding at the drum, (excessive dripping at

spindle area),is cause by one of two reasons:

1. Level sensors set to high

2. Improper Draining

First check your level sensors for proper

adjustment. This procedure is explained in your Manual.

If the levels appear to be correct, check your

dump and save (if used) lines. If lines are run incorrectly, they will restrict the flow

of solution from the processing drum, causing a incomplete drain.

This in turn will leave solution I the drum

thus off setting the capacity of the drum.

First make sure that the ends of the lines are

not under liquid. (Lines are extending to far down in the dump or save containers)

Remove your dump line and replace it with a

very short piece of tubing, about 18 inches, and let it dangle over a bucket. Take your

largest processing drum and remove the top and insert it in the machine. Fill the drum

with water and select " DRAIN " from the plus button on the machine. Repeat this

process 4 to 5 times. If the processing drum drains completely at the end of each drain,

then the problem is in the way the dump line is run. If the drum does not drain

completely, the problem is internal. Something has become lodged in the valve assembly

inside the machine. The valve must be disassembled and cleaned out.

Look in the manual for the location of the

valve assembly inside the machine. Remember:

UNPLUG MACHINE AND COVER CIRCUIT BOARD

Back

Flooding from Overflow

Water coming out of your overflow port in the

rear of the machine is caused by a restricted flush line.

Check Manuel for proper installation

Back

Machine does not move from "Heating

Preheat" or "Heating Developer" in

E6 or C41

If when you first start an E6 or C41 process, the machine does not

move from "Heating Preheat" or "Heating Developer", check the status

of the display. If the display is bouncing back and forth from "Heat on" to

"Heating Preheat" or " Developer ", add 2 ounces of the hottest tap

water you have to the heating chamber. You can access it from behind the black door on the

right hand side of the machine. If the machine suddenly continues on with the process,

this indicates a bad heating chamber and must be replaced.

If the display is indicating one message "Heating Preheat"

or " Developer", the selector valve has not successfully made it to its next

port. If you have a Linear Selector valve,(13 stainless steel tubes) you must run the

"Lube Cycle" about 3 to 4 times. If after lubing, the problem still exists, call

Tech Support at PhotoTherm .

If you have a Rotary selector valve,(circular plastic) you may have

gotten chemicals on the timing wheel and the selector valve has lost its position. Open

unit and inspect the cut aways on the wheel for evidence of any chemical build up. Gently

rotate the wheel and use rubbing alcohol and any ridged object to clean of the chemicals

in the cut aways

If the problem still exists, call Tech Support at Photo Therm

Machine wont Initialize-Stuck in

Process

Linear selector valve

If the SideKick wont initialize or is stuck in

a process, and you have a linear selector valve,(13 stainless steel tubes in the rear of

the machine), your selector valve is jammed.

You will need to purchase a can of spray

silicone.

On the right side of the unit, towards the

rear, is a circular plastic cap.

Remove the cap and spray the silicon into the

cylinder area of the selector valve. Let set for 10 minutes. Try turning the unit on and

see if it will initialize.

If it does not, repeat the process.

If you are successful, Run the lube cycle 4 to

5 times.

If the machine still will not initialize, call

Tech Support.

Machine wont

Initialize-Rotary selector valve

If the SideKick wont initialize and you have a

rotary selector valve,

(circular with 18 tubes), the most common cause

is chemical build up on the sensor wheel located inside the unit causing it to loose

position.

First open the machine and remove the rotary selector valve. Carefully disassemble the valve and clean the

wheel and face plate with hot water and soap. Concentrate on cleaning the cutaways on the

sensor wheel, located under the triangular pressure plate.

USE ONLY A PAPER TOWEL TO CLEAN PARTS WITH,

NOTHING ABRASIVE!

Reassemble the selector valve and mount it back

on machine.

Turn unit on. The machine will position the

selector valve automatically

Machine Failure

If the machine indicates machine failure, this

usually indicates a bad temperature sensor, a part which can be ordered and installed with

ease.

Back

Muddy Looking Slides

If your slides have a "muddy" look to

them, this is from under bleaching. To eliminate other causes, try, in 7 step

chemistry, rebleaching your film, in 4 step reblixing. Roll the processed film back on a

reel and place the reel in a small container. Fill the container with enough fresh bleach

or blix to cover the reel. Let sit for 10 minutes. Remove from the container, wash the

film off and dry. If the film clears up, remix the bleach or blix.

If rebleaching had no effect on the look of the

film, call phototherm tech support.

Back

Chemicals are not picked up by

Level Sensors

If the machine will not stop pumping up solution into the heating

chamber,

and there's evidence of solution coming out the flush line, you are

using distilled or deionized water, which must be changed to regular tap water, or the

heating chamber has lost a ground wire from underneath.

To see if this is the case, make sure the heating chamber is full of

water.

Select "Drain" from the plus button, then press start. If

the pump stops before the heating chamber is empty, the ground wire, a green wire that is

soldiered on the underside of the heating chamber to the metal base, has come off.

Resolider the wire in the exact spot from which it came off, and retest.

Back

No Display

The display on the unit is written to independently and has no effect

on the machines performance. If the display goes out or you experience garbled wording,

the display most likely needs to be replaced.

Back

Not Recognizing Drum- SK4

The most probable cause of the SK4 not

recognizing a drum is a faulty sensor mounted in the unit. For the four roll drum, the

sensor is mounted above the heating chamber to the side of the body. The two roll sensor

is mounted on the opposite side of the machine on the side also.

These parts can be ordered and easily

installed.

Back

Not Recognizing 8 Roll Drum-SK8

If the SK8 does not recognize the drum, first

clean the contacts on the machine and the drum. Gently push the contacts together on the

machine.

Insert the drum and try again. If the drum is

still not recognized, try inserting the other drum. If the machine operates properly, the

problem is with the one drum. Usually this means the sensor inside the drum has failed and

the drum needs to be replaced.

If neither drum is sensed by the machine, a

problem exists with one of the wires attached to the back of the contacts inside the

machine.

Open the unit and inspect each contact from the

inside.

On one contact you will find a red wire, and on

the other you will find a green.

Make sure both wires are tighten to the

contacts, and that they are not touching each other.

If all the above seems good, call the tech

support at Photo-Therm

Back

Rotation Motor Stops

The most common cause of a rotation motor stopping is bent pins on

the spindles, causing the spindle to bind against the processing drum.

To test, start a "DUMMY" process, ( no film in processing

drum).

When the motor starts to rotate slowly or stop, pull back on the

processing drum until the spindle disengages from the staple bushing.

If the motor picks up speed, the problem is with the pins on the

spindle.

If there is no change in the motor speed, it must be replaced.

Call Photo-Therm to arrange to have the pins on the spindle repaired.

Back

Spots on Film

There are several causes of film spotting. The

most common is stabilizer or photoflo that is over concentrated. Small bubbles form and

dry on the film causing spots. If, after you process, notice bubbles or foam on your film,

this is an indication of over concentration.

1.Cut the mixing ratio of your stabilizer or

photoflo by half. ( one half on concentrate to recommended water)

2.Check your areas water supply. Some areas

have a high level of calcium. Calcium will leave small spots on your film. Rinsing the

film under water and using a rubber wiper will help.

3.If your using the dryer on the sidekick, you

must leave the reels on the spindle when drying. If your putting only the reels in the dry

tube, the air flows through the center causing uneven drying and spotting

Back

Streaking in the End Frames

Streaking in the end frames is due to insufficient chemistry

in the processing drum. This can be caused by several different factors: incorrect level

settings in the heating chamber, a slow leak from the valve assembly, or having your unit

unleveled.

1. Check your level sensors for proper adjustment. Refer to

your manual for the procedure.

2. If your level sensors are set correctly, remove your dump

and save tubing from the back of the unit. Insert the largest processing drum in the unit,

with no lid and a spindle with a reel on each end in place. For a FP1 or Sk4 processor,

pour in 14 oz of water. For an Sk8, pour in 29 oz. Inspect the height of the water

in relationship to the center of the front reel and the back. If the water appears

to be higher in level on one reel as opposed to the other, the machine is not "true

level" and must be shimmed on one side to equal the level for both reels.

3. If after pouring the water in the drum as directed in

step 2, you find the water level is equal on both reels, let the drum sit for about

10 minutes. During that time, check for dripping from the dump or save stainless steel

tubes in the back of the unit. If dripping occurs , the valve assembly must be removed and

cleaned. Usually a foreign object has lodged itself inside keeping the valve open slightly

causing a slow drain during processing.

If you still have problems, contact PhotoTherm tech support.

Back

PhotoTherm

Super Sidekick

Automatic

Film Processor

Model SSK-8R

8 Roll Auto Replenishing

Owner’s Manual

US PATENTS RE 34,188 & 5,379,086

Please record the Serial No. ____________ and date of Purchase __________

Please mail in your warranty card.

TABLE OF CONTENTS

2 Description |

11 Test Mode |

18 B&W Dev. Times |

2 Setting up |

11 Diagnostics Mode |

19 4x5 processing |

5 Preset Selections |

12 Maintenance |

20 Automatic Replenishing |

6 Processing |

13 Alarms and messages |

21 Service–Correcting Problems |

7 Drying |

14 Hints |

24 Parts list |

8 Reel loading |

15 Process Parameters |

25 Wiring |

9 Special functions |

17 Chemicals |

26 Phone #’s & Log |

| 9 Normal Mode |

17 Other Processes |

|

| 10 Program Mode |

18 Push Processing |

|

WARRANTY

Each PhotoTherm product is produced under rigid quality control standards. This unit is

fully warranted for a period of one year from date of purchase. PhotoTherm 110 Sewell Ave

Trenton NJ 08610 USA Tel 609 396-1456 Fax 609 396-9395.

110 Sewell Ave. Trenton, NJ 08610 USA Tel 609 396 1456 Fax 609 396 9395

Email serve@phototherm.com

DESCRIPTION

The SSK-8R automatic processor accurately tempers each solution, one at a time. This

design breakthrough allows B/W processing at 75 oF and then immediately

afterwards slide processing 100 oF. Tempered water is not needed. Long warm-ups

are not required.

All the solution bottles for processing color slides, color negatives and Black and

White negatives are constantly connected. The operator just selects the process. The unit

pumps the proper chemical from any of the 18 reservoir containers, quickly heats the small

volume needed to the correct temperature and starts processing. As it processes one

solution it prepares the next solution. At the end of the process cycle it automatically

flushes itself clean, preparing itself for the next process.

Back

The SSK-8R is compact (26" wide by 14" high by 16"

deep). The process drum is removable for loading in a dark box or

bag. The SSK-8R can process 8 rolls of 35, 5 rolls of 120/220 or 8 sheets of 4x5 at one

time. Two chemicals can be automatically saved from each process for silver recovery,

reuse or automatic replenishment. Fresh developer is used for quality. The standard

processes are pre-programmed, but the developer time can be easily changed when desired.

Back

The SSK-8R can be set up for any of 4 slide, 4 color negative and

3 B&W processes. The

operator can change the time of, or eliminate any process step. The operator can select

which solutions to save. The SSK-8R anticipates problems and takes automatic corrective

action.

The SSK-8R protects the film from possible operator errors. It has an interactive

computerized display that prompts and informs the operator what it is doing. Possible

operator errors are also minimized because, chemical lines do not have to be switched nor

must volumes of solutions be measured.

Back

SETTING UP THE UNIT

The unit comes packed in 2 boxes. Make sure you received the

following:

| ... 8-reel and a 4-reel black

processing drum with lids ... 8-reel and a 4-reel spindles with impellars.

... 10 plastic film reels

... Main processor SSK-8RG

... Spacer 2-roll (white fat donut)

... Utility dryer tube. (White plastic 4" diameter 11" long |

… Dryer spindle. (10"

long without an impeller) ... Coil of ¼" flexible tubing

... Power cord

... Six ½ gal. (2 liter) solution bottles with fittings

... Six 1 gal. bottles

... Two 1 gal Holding bottles

... 10 Film Clamps for 120/220 film.(white curved plastic pieces) |

... Two 1 gal. collapsible

bottles ... Water bottle (5 gal) with float valve

.. Saddle valve kit to connect water bottle to water pipe

... Dump bottle (5 gal) with level sensor and cap with

…3" gray plastic fitting to hold the dump and flush tubing

... Plug to seal COUPLING when FLUSHING |

... Syringe of silicone grease ...

Allen wrench (1/16") for bushings

... Magnetic stirrer. A white "pill" (3/8" x 1")

... Permanent marker

... Piece of Scotch Brite

... Set-up video

... This instruction book |

Back

SETTING UP THE UNIT

Place the unit on a flat level surface. Lift up the side and cut away and discard the

two visible nylon straps from the bottom of the unit. These straps hold the pumps secure

for shipping and must be removed for the pumps to work.

Prepare the solution bottles. a) Loosen NUT. b) Push in notched end of the ¼ OD black

tubing through fitting to bottom of bottle. Leave about 2 inches (5 cm) exposed. c) Hand

tighten nut. d) Rinse out bottle. You can use the collapsible bottles for developers; they

will extend chemical life because there is no air interface.

Use the marker pen to label each bottle and lid with the chemical it contains. Cut a

piece of clear flexible tubing long enough to run from the bottle to the back of the

machine. RUN THE TUBING STRAIGHT DOWN from the back of the machine. After about a foot,

the tubing can run in any direction Allow about 2 feet (60 cm.) extra for slack. Label

both ends of the tubing with the chemical name. Slip one end over the proper tube and the

other end over the exposed black tubing of the solution bottle. The 5 gal. Water bottle

connects to the WATER (#5) tube.

IMPORTANT. The solution source bottles must be located below the processor.

The 5 gal. water bottle, which has a float valve near its lid, holds the water that

will be used for processing and internal cleaning (FLUSHING) of the unit. You can manually

fill the bottle. Use regular tap water, not de-ionized or distilled water. You can connect

the bottle to a cold water pipe for automatic filling with the "ice maker" kit.

TURN OFF THE WATER AT THE SOURCE WHEN THE MACHINE IS NOT IN USE.

The DUMP bottle comes with a level sensor that should be plugged into the DUMP SENSOR

jack on the back of the unit. IT WILL SENSE IF YOU HAVE ENOUGH ROOM FOR A 2 or 4 ROLL RUN

ONLY. The bottle must be emptied if you are doing a 6 or 8 roll run. If a plumbed-in drain

is available, use it.

There are five drain outlets in the back of the unit:

1. DUMP - For spent chemistry. Connect to DUMP bottle or plumbed-in drain.

2. FLUSH - Disposes of spent FLUSH water. Connect to DUMP bottle or drain.

3. SAVE FIX - Recovers the solution to be saved. Active only when SAVE

switch is on (red is showing). Connect to separate bottle.

4. SAVE BLEACH - Recovers solution to be saved. Active when SAVE switch

is on. Connect to separate bottle.

5. OVERFLOW - DO NOT CONNECT. If solution comes out of this outlet, check

your FLUSH tubing for proper installation.

Push the flexible tubing over the stainless tubes of these outlets (not more than

3/4").

Very Important

Position DUMP bottle close to unit. (Fig. 1)

Run tubing directly to DUMP bottle. (Fig. 1)

Cut off unneeded length of dump tubing. (Fig. 1)

Run the DUMP and the FLUSH tubing separately into the 3" gray fitting on the DUMP

bottle. Do not put a third tubing into the same fitting. Do NOT run tubing inside DUMP

bottle. (Fig. 2). Allow at least 12" drop between unit and DUMP bottle.

Open the DOOR by lifting up from the bottom and pulling out. Place the magnetic stirrer

(white pill) in the exposed heat tank. Carefully push the stirrer with a pencil until it

is magnetically caught near the back right corner of the tank. Turn SIDEKICK on and check

if the stirrer is turning.

Put in six Alkaline "C" Cells in the battery holder. This will allow the unit

to continue after a power failure and protect it against power surges. Plug the power cord

into a 120 Volt AC 15 Amp. (regular domestic) outlet.

The batteries will protect SSK-8R from short power losses. You can also connect SSK-8R

to a TRIPP Model Pro 1400. A 1400 Watt Uninteruptable Power Supply, which would allow the

unit to finish the process in case of a long power failure.

PROGRAM the USER CODE. You have to program the user CODE before

you can use SUPER Sidekick (SSK). This is only done once.

Turn off SSK for at least 10 seconds. Hold down the START switch as you turn SSK on.

Release the START switch. SSK will show the programming instruction. (See PROGRAM MODE for

a fuller explanation). SSK will then display "USER CODE" " # (any

number)". Change the number by pressing – ( MINUS) telling SSK you want to make

a change. Then pressing PLUS(+) to increase the number. When "7" is displayed,

press START. SSK will record the information. After it is finished "RECORDING",

you can use PLUS to look through all your options or just turn SSK off.

Make sure SSK is level by inserting the bottom half of the large DRUM in the SSK. Pour

water into the DRUM until it is about ½" from the top. Measure the distance from the

water to the top of the DRUM at the front and the back of the DRUM. Level the SSK with

shims until the distances are equal. Run DRAIN to empty the DRUM. See SPECIAL FUNCTIONS.

See PROGRAM MODE to select the set processes. Run the DUMP TUBING TEST to verify

correct tubing installation. See TEST MODE.

Back

PRESET SELECTIONS

Selections as shipped from the factory. See PROGRAMMING to change selections (values).

Name |

Preset |

Choices |

| Unit Code |

0 |

Must be changed to 7 to operate. |

| Replenish Percent |

00% |

|

| Slide Dev Time |

6:30m |

|

| Color Neg Dev Time |

3:15m |

|

| TriX/PlusX Dev Time |

4:40m* |

|

| Tmax 100/400 Dev Time |

5:30m* |

|

| Tmax 3200 Dev Time |

5:45m** |

|

| Dry After Process |

No |

Yes, to use built in dryer |

| E6 Slide Process |

4 Step |

7 Step, with or without prewet |

| Color Neg Process |

C41 |

Bleach+Fix, with or without prewet |

| Set all Times |

Standard |

Change any time as needed |

| Save as Bleach |

None |

Any solution |

| Save as Fix |

All Fixes |

Any solution |

| Rotate RPM |

40 RPM |

10 to 50 RPM (Rotations/Minute) |

* 75oF (23.9oC) ** 85oF (29.3oC)

PROCESSING

In a dark box, load the film on the reel (see REEL LOADING). Slide the reel on the

spindle with the film guide pointing in the direction shown. If there is room on the

spindle, use the SPACER (goes on last) to conserve chemistry. Place the spindle inside the

FILM DRUM. Cover the spindle with the lid (one side is shaped to go over the spindle).

Slide the clips towards the ends of the FILM DRUM to close it. You are now light tight.

Push the FILM DRUM to the left in the TROUGH till the SNOUT seats itself inside the

COUPLING. The two stainless pins of the spindle should go on opposite sides of the STAPLE

on the rotate motor.

Look to make sure you have enough solution in the chemical bottles. Empty the DUMP

bottle. Turn the unit ON. Use PLUS to select the type of film you are processing. Push

START to begin the process.

The unit will ask you how many rolls (35 mm) are being processed. Use "PLUS to

select : "2" for 1 or 2 rolls of 35mm or 1 roll of 120/220. Use SPACER.

"4" for 3 or 4 rolls of 35mm, 2 rolls of 120/220 or a 4x5 sheet film holder.

"6" for 5 or 6 rolls of 35mm, 3 rolls of 120/220 or 2 4x5 holders (8 sheets).

Use SPACER

"8" for 7 or 8 rolls of 35mm, 4 or 5 rolls of 120/220.

The SSK uses 2 oz. (60ml) of solution per run, plus 3 ½ oz. (105 ml) per roll.

If you want to change the developing times see PUSH PROCESSING.

The unit will load the first solution into the internal heating tank, heat it to the

proper temperature, warm the processing drum with warm air and then start the process

automatically. As the unit is processing one solution it prepares the next solution. The

film DRUM has an independent secondary temperature controller that controls the warm air

blowing on the DRUM to maintain accurate temperature. The temperature in the DRUM is

continuously measured and the time slightly adjusted for a final tweak of the processing.

This fine tunes the solution to an accurate temperature for very consistent results. When

one solution is finished it is drained out and the prepared solution in the heating tank

is pumped into the DRUM. The same procedure is repeated for all the necessary solutions.

The unit will signal at the end of the wet processing. Remove the PROCESS DRUM. Insert the

PLUG in the COUPLING and wipe out the TROUGH with a paper towel.

Back

DRYING

Up to 4 rolls of 35 mm film can be dried in the included UTILITY DRYER on reels. The

film can also be dried any other way. The base of 120 film is too thin for drying on a

reel, and must be dried by other means.

Place the UTILITY DRYER vertically in the TROUGH so that the cut away portion of the

DRYER covers the air vent in the side of the TROUGH. Shake out each reel 4 times over a

sink with a vigorous snap of the wrist to remove excess solution. Put the reels on the

dryer spindle (closed end on the bottom) and put the spindle in the UTILITY DRYER

Push START to begin drying. SSK will FLUSH itself as it is drying the film. The unit

MUST BE ALLOWED TO FLUSH itself after every processing run. The required drying time will

vary with the amount of film and the relative humidity of the room. If the film is not

fully dry when the dryer stops (15 min.), dry again. Rinse all reels, spindle and drum

with COLD water. Room air dry - hot air may distort the parts. RINSE, DO NOT IMMERSE THE

DRUM.

If you get drying marks, try the following: a) use distilled water for the last step.

b) dilute the wetting agent or stabilizer. c) use softened water. d) rinse externally in

distilled water. e) squeegee and hang up to dry. Film with drying marks can be re-rinsed

and dried again.

An accesory hang-up dryer is available from PhotoTherm (Part# AF-DR8).

Back

REEL LOADING

The plastic ratcheting reels can be adjusted to hold different sizes of film. Simply

hold the reel in both hands, making sure that the outer spiral groove (near the ball

bearings) is on top and facing you.

Twist the right half of the reel clockwise until you hear a click. The two halves can

then be pulled apart. There are 3 "keyed" positions on the reel hub. The

narrowest position is for 35mm or 126, the second for 127, and the widest for 120/220.

Insert the leading end of the film, emulsion down, into the outer spiral groove of the

reel and an inch past the ball bearings. With both hands on the reel twist the right half

and the left half in opposite directions. You may have to assist the film feeding by

placing the thumb, of your forward moving hand, on the outside of the film.

Keep feeding the film until the end clears the ball bearings.

Any Paterson TM reels will work. They are available at most photo stores.

Contact Photo-Therm if you prefer to use different style reels.

35 MM FILM Cut off the film leader. Clip the corners of the leading end to make feeding

easier. 35 mm film can be started past the ball bearing in the light, but must be fed into

the reel in the dark. Twist one side of the reel back and forth to feed the film into the

reel. When you reach the end of the film use scissors to cut it away from the film

cassette. Do not tear the film. An uneven tear may cause the film to come off the reel.

Back

120/220 film comes off

during process

120/220 FILM. Separate the tape from the backing paper and fold it back over the film.

This will stiffen the end of the film. Load the taped end into the reel. Feed until the

back end passes the ball bearings.

Bend a 120 Film Clamp and place it over the end of the film into the grooves of the

reel, close to the ball bearings, as shown above. Add a second film clamp on top of the

first one. For extra assurance use a 1 in. piece of leader tape to bond the end of the

film to the film clamp.

Mount the 120 reels in the center of the spindle.

SPECIAL FUNCTIONS

Just turn the power switch ON for normal operation. Hold down the START switch as you

turn the power switch ON to be able to PROGRAM process values. Hold the PLUS switch when

turning on to see the roll count and run DUMP tubing test and valve test.

Hold MINUS when turning the unit on to put SSK-8R in DIAGNOSTIC mode.

MODE |

Hold when switching ON |

Description |

NORMAL |

Nothing |

Normal Operation |

PROGRAM |

START |

Changes processes and set values. |

TEST |

PLUS + |

Tests Valves and DUMP lines. Displays Roll

count. |

DIAGNOSTICS |

MINUS - |

Technical diagnostics. |

NORMAL MODE Special Functions

Selected with PLUS when machine is turned ON.

DRY will turn on drier for 15 minutes.

DRAIN will empty the internal HEAT TANK and the PROCESS DRUM.

CLEAN LINES is a major cleaning. It draws solution through each

of the chemical tubes, one at a time, starting with tube #18 and ends with #1 and then

does a FLUSH using #5 as a water source.

All solution tubing should be removed and the water tubing moved manually from position

to position, as the unit draws water through each tube to clean itself.

Back

CALIBRATE will load water into the heat tank, heat it and hold

the temperature at 37.8 oC (100 oF). The unit will emit a beep every

time it reaches the proper temperature. Allow 15 minutes after the first beep before

reading temperatures. Check the temperature with a digital thermometer (an electronic

fever thermometer works great) with the probe near the stir rod but not touching the

bottom of the heat tank. A glass or dial thermometer will not work. CALIBRATE also

measures the number of pump pulses needed to cover the level sensors. This information is

necessary for replenishment with the SSK-8R. If you run out of water during calibration,

rerun the calibration.

The temperature can be adjusted with a small screwdriver through a hole on the left

side of the unit. Clockwise to decrease temperature. All units are calibrated at the

factory and should not need adjustment in the field.

Back

The DRUM Temperature sensor can be tested by holding MINUS when

"CALIBRATE" is displayed and then pushing START. The bottom display line shows 2

Hex numbers. The first Hex number refers to the DRUM temperature sensor. At room

temperature (70 oF, 21 oC) the Hex number should be B5,B6,B7,B8,B9

or BA. The important thing is that it should not vary by more than 2 on any successive

reading. If it readings are erratic, clean the Stainless Steel contact plates with alcohol

and Scotch Brite, and squeeze in the contactors on the body.

Back

PROGRAM MODE will allow you to change the set processing values. Select by holding

START as you turn SSK on.

SSK will first show you programming instructions.

Use MINUS when you want to change settings. Minus will also lower the time when

changing times.

Use PLUS to advance the selections and increase the settings.

START records the changes.

Turn the power switch off to exit programming.

Change # to 7 for the unit to operate. Push MINUS to make a change. Push PLUS until 7

is displayed and then push START to record the change. This is only done once when you

first get Super Sidekick. After recording either turn off the unit for at least 10 seconds

to exit or push PLUS to look at the next parameter.

Changes the percent of replenishment. Push MINUS to change. One number at a time will

start blinking. Use PLUS to increase the number. Push MINUS to move to the next number.

When all the numbers are correct, push START to record.

The next few screens let you change the set developer times. (Changing the developer

time for one processing run only (Pushing), is done during normal processing as the

process is selected.)… push MINUS to make a change, use PLUS and MINUS to select the

time and then push START to record.

If you want to use the included utility dryer right after processing, set to

"YES". If you will dry the films externally (recommended), set to

"NO".

Select the slide process you want to use: whether 4 or 7 step, with or without prewet.

You can also choose not to show slides as a selection to the operator.

Select the color negative process you want to use: C-41 or bleach & fix combined,

with or without prewet. You can also choose not to show color negatives as a selection.

You can change the time of any step in any process. You can remove any step by making

the time less then 2 minutes. In Black & White any changes after developer affect all

the Black & White processes. Push MINUS to make changes, push PLUS to select the

process, then push MINUS to change the times in that process. PLUS selects the solution,

MINUS will let you make changes and then PLUS and MINUS change the time. START records the

selection. Exit by turning Super Sidekick off.

Select the solutions you want to save to the BLEACH SAVE and FIX SAVE tubes. Push MINUS

to make a change, push PLUS to select the process, then push MINUS to change the solutions

you want to save in that process. PLUS changes the choice (Yes or No) and START records

the change. Exit by turning Super Sidekick off.

You can change the rotational speed of the spindle. Push MINUS to make a change. PLUS

will advance the selections and then START will record the changes.

Will change all parameters to their original settings when Super Sidekick was shipped

from the factory. Just press START.

TEST MODE Select by holding PLUS as you turn SSK ON. It will first display roll and run

counts and then show the number of pump pulses used to cover each of the level sensors.

DUMP TUBING installation is tested by pumping up water into the large film drum and

letting it drain out. The cycle is repeated 3 times. Connect the DUMP and FLUSH tubing to

your drain or bottle. Fill the water bottle with water and connect it to tube #5. Insert

the large DRUM into SSK, keep the top off so you can observe the action. The DRUM should

fully empty every time it drains. If it does not, turn the unit off and recheck your DUMP

tubing. You can empty the HEAT TANK and DRUM by running DRAIN in NORMAL MODE.

The VALVE TEST is selected by pushing PLUS. Insert the PLUG into the coupling. When you

push any switch, a valve will open and the FILL pump will turn on as long as you hold the

switch. It will pump any solution in the HEAT TANK out of the DUMP/SAVE tubes. You can use

the CALIBRATE function in NORMAL mode to pump some water into the HEAT TANK.

The SAVE switch will indicate ON (red showing) on the display if it is on during the

VALVE TEST.

DIAGNOSTIC MODE

Select by holding MINUS as you turn SSK ON. This

is a technician level area. Acknowledge you are technically qualified by pressing PLUS.

This mode individually checks all of the machine function, sensors and actuators. SSK

may have to be opened to reach some of the sensors. See SERVICE.

Will display any level sensor that senses solution. SSK has the following Level

sensors: Low, 2-roll, 4-roll, 6-roll, 8 roll, drain level (located inside the coupling)

and the rotary selector valve (SSK-8R only). The SAVE switch can also be tested as a level

sensor.

You can test the sensors by connecting a clip lead between the solder lug on the side

of the HEAT TANK (central grounding [earth]) and the sensor.

If none of the level sensors is made, you can push MINUS to go to the VALVE test, PLUS

to go to the PUMP test and START to go to OTHER tests.

Pushing the switches will open the valves. (The valve test in TEST MODE allows you to

check flow through the valve by also turning on the FILL pump). Hold MINUS and push PLUS

to go back to LEVEL TESTER. Pumps are tested the same way. AUXILIARY is reserved for

future needs.

DR&ROT (push MINUS) will turn on the dryer and the spindle ROTATE motor. TEMP (push

PLUS) will show the HEX readings of the DRUM and HEAT TANK sensors, show the voltage

(120/230) and then take a few readings in HEX of the actual voltage.

GAT (push START) will exercise the ROTARY SELECTOR valve to both ends of travel, then

stop at tube #9. This is the middle of travel and is the position the valve must be in

when its internal tubing is mounted.

MAINTENANCE

Wipe off all spills when they occur.

Keep the stainless contact plates on the DRUM clean. Never touch with fingers. Clean

daily with alcohol and buff with Scotch Brite. Bend in the contactor springs on the body

periodically.

Use silicone grease to lubricate the "O" ring on the SNOUT of the processing

DRUM as needed.

Inspect the plastic sleeve on the STAPLE that turns the spindle - replace if worn.

Clean the reels as needed by soaking in a 50% solution of household bleach for 5

minutes. Rinse well with hot water.

ONCE A YEAR, open the unit (see SERVICE), unplug it first, and:

1. Protect the PC board from getting wet. Cover it with paper towels and a plastic

sheet.

2. Examine for any signs of wetness.

3. Clean the heat tank and the area above the heat tank with a cloth dampened with a

toilet bowl cleaner.

4. Replace the air filter on the dryer with a 3" square of air conditioner filter.

5. Remove the protection for the PC board and push down on all the connectors.

6. Close up the unit.

ALARMS & MESSAGES DO NOT TURN UNIT OFF until you check why.

A continuous series of short buzzes signals that the unit requires attention. Read the

message in the display to find out what needs to be done.

Back

DISCARD DEV! SEE BOOK ERR# 1 means that the developer did not

drain out. Work quickly, but calmly. The film is safe.

- Pull the film DRUM out and quickly stop up the end of the snout with your finger.

- Go to a sink or bucket and let the developer drain out of the snout.

- Re-insert the DRUM back into SSK.

The process will then continue, but check to see why the solution did not drain.

Back

CHK DRAIN TUBES SEE BOOK ERR# 2 means that some solution (not developer)

did not drain. Push start to stop the buzzer. Check your drain tubing. Is the tubing

crimped? Is the DUMP bottle full? When you have found the problem, correct it and push

START to let the process continue.

CHECK "SOLUTION NAME" means that there is not enough

solution for the processing to continue. Push START to turn off the alarm. Fill the

solution bottle and then push START. The process will continue.

FLUSH means that the unit was not flushed after the last

processing run. Push START to allow unit to flush itself.

NO AC means the unit is not plugged in. Plug the unit into a live

wall outlet.

DUMP TANK FULL Empty the DUMP bottle.

PLEASE TURN OFF Turn unit off when not in use. There is nothing

that needs warming up.

MACHINE FAILURE Problem with heat TANK temperature sensor. See

CORRECTING PROBLEMS.

SET CODE SSK code must be set before it can operate. See PROGRAM

MODE.

Back

CLEAN DRUM SENS! SSK has tested the DRUM temperature sensor and

determined that it needs cleaning. Wipe with alcohol to remove grease and fingerprints.

Buff with Scoth-Brite. Push in the contactor springs.

Back

CLEAN LEVEL SENSRS SSK has determined that one of your level sensors in

the heat tank may have some slime or a hair hanging from it. Open the unit (see CORRECTING

PROBLEMS / OPENING the UNIT) and clean off the sensors. Check for any moisture inside the

unit.

Back

REPL FILL PUMP SSK has determined that your FILL pump needs replacing.

Back

WAIT FOR AC If message flashes on and then goes

away do not worry. If the message stays on it means that developer has not touched the

film yet and that you are connected to a Uniterruptable Power Supply (UPS). SSK will wait

for AC electrical power to be restored before continuing the process. If the film was

already in developer when the power outage occurred, SSK will continue the process on UPS

power.

HINTS

Test a new batch of chemistry on your own film or run a test strip.

Back

PROCESSING PARAMETERS

S O L U T I O N, T i m e, T e m p ,T u b e ,C O M M E N T S

E6 Slide Processes.

7 Step E6 slides without prewet.

Air Preheat Varies to 37.8 Go to SLD DEV below

7 Step E6 slides with water prewet.

WATER prewet Time Temp 5

Checks drum temp

SLD DEV eloper 6:30 37.8 2 Very precise

WATER wash (3x) 2:00 37.8 5

SLD REV ersal 3:00 37.8 18

SLD C olor DEV 4:00 37.8 17 Very precise

SLD CONDitioner 3:00 37.8 16 pre-bleach

SLD BLEACH 8:00 37.8

6

COLOR FIX 4:00 37.8

13 SAVED FIX if switch ON

WATER wash (3x) 2:00 37.8 5 also used by C41 FIX

SLD STABilizer 2:00 23.9 9

4 Step E6 Slides without water prewet. Go to SLD DEV below

4 Step E6 Slide with water prewet. PRESET

WATER prewet Time Temp 5

Checks room temp

SLD DEV eloper 6:30 37.8 2 Very precise

WATER wash (2X) 2:00 23.9 5 Acts as cool stop

WATER wash 2:00 37.8

5

SLD C olor DEV 4:00 37.8 17 Very

precise

WATER wash (2X) 2:00 23.9 5

WATER wash 2:00 37.8

5

SLD BLIX 10:00 37.8

6 SAVED FIX when switch is ON

WATER wash (3x) 2:00 37.8 5

SLD STAB ilizer 2:00 23.9 9

Color Negative Processes.

Color Negative C41 without prewet. Go to C41 Dev below

Color Negative C41 with prewet PRESET

WATER preheat Time Temp 5 Checks drum

temp

C41 DEV eloper 3:15 37.8 3 Very precise

C41 BLEACH 6:00 35.5 8

WATER wash 2:00 35.5 5

COLOR FIX 6:00 35.5

13 SAVED FIX if switch ON

WATER wash (2X) 2:00 35.5 5 also used by E6 FIX

C41 STABilizer 2:00 23.9 10

Color Neg. Bleach+Fix combined no prewet. GO to C41 DEV

Color Negative Bleach+Fix combined with prewet.

WATER prehwet Time Temp 5 Checks room

temp

C41 DEV eloper 3:15 37.8 3 Very precise

C41 BLIX 3:00 35.5

8 SAVED FIX when switch is ON

WATER wash 2:00 35.5

5

C41 STAB ilizer 2:00 23.9 10

Black & White Processes. All are available in NORMAL MODE.

TRI X / PLUS X

B&W DEV eloper 4:40 23.9 4 end of BW

process is same

TMAX 100 / 400

B&W DEV eloper 5:30 23.9 4 end of BW

process is same

TMAX 3200 This is a warmer process 85oF (29.3oC)

vs 75oF (23.9oC)

B&W DEV eloper 5:45 29.3 4 end of BW

process is same

END OF BLACK & WHITE Common to all BW processes.

WATER wash 2:00 23.9

5 also acts as stop

B&W FIX 7:00 23.9

14 SAVED FIX is switch ON

WATER wash 2:00 23.9

5

B&W P erma WASH 2:00 23.9 15 hypo clear or

water

WATER wash 2:00 23.9

5

BW RINSE 2:00 23.9

11

CHEMICALS

BLACK AND WHITE

Use: 1. Kodak T-Maxim developer (B/W DEV) 2. Rapid B/W FIX 3. Hypo clearing

agent (B/W P WASH) such as Heico Perma-Washtm 4. B/W RINSE Photo-Flo (Kodak) or

Rexton’s Hyperwettm. Mix T-Max developer 1 part concentrate to 5 parts

water. It works better in a Sidekick than Kodak’s recommendation of 1:4.

COLOR NEGATIVES C-41

Use working strength solutions of any C-41 chemistry. Overflow solutions work well. If

you use replenishers remember to add starter to the developer to get a working strength

solution.

RA C-41 chemistry works well with the standard bleach and fix times. If you would like

to shorten the bleach and fix times see PROGRAM MODE.

SLIDES 7 STEP E-6

Back

Blue shift can be

corrected by adding sodium hydroxide (see chem. manufacturers instructions) to the color

developer or by diluting the reversal step. When reversal is too dilute, the slides will

have a green cast.

Bleach should be aerated (have air pumped through it). Use a fish tank type air pump

and run the tubing to the bottom of the bleach bottle. Do not use an airstone. Run for at

least 2 hours a day. Check reversal for scum growth - discard, clean bottle, re-mix. Check

color developer for separation - re-stir with mixing rod.

Back

SLIDES 4 STEP E-6

Unicolor, Photo-Technology, Tetanol or Beseler chemistry will work. (Some manufacturers

call their chemistry 3 step - they don’t include a wetting/stabilizing step. Use C-41

stabilizer or a wetting agent (Hyper-wet or Photo-Flo) for this step.

PROCESSES OTHER

MOTION PICTURE FILM (black layer on base). Process ECN-2. Process like normal C-41

film. Since SIDEKICK can use fresh solutions for each step, the black residue does not gum

up the unit. Turn SAVE switch OFF. After the last step, rinse under warm water and gently

rub the remaining residue from the film base. Do not touch the emulsion. Hang film to dry.

Wash reels with a soft brush in dish detergent.

Mix color chemistries in water that is at least 85 oF (29 oC).

Stir well. Wait one hour before using.

PUSH PROCESSING.

| Film |

Time |

Push 1 Stop |

| Agfa 201 440-2500 |

| APX 25 |

4:15 |

5:15 |

| APX 100 |

4:15 |

5:15 |

| AP 400 |

4:50 |

5:45 |

| Fuji 800 788-3854 |

| Neopan SS |

4:15 |

5:30 |

| Neopan 400 |

4:40 |

5:50 |

| Neopan 1600 |

3:30 |

4:40 |

| Ilford 201 265-6000 |

| HP5 PLUS |

4:30 |

5:30 |

| 100 DELTA |

4:30 |

5:30 |

| 400 DELTA |

5:00 |

6:00 |

| Delta 3200 |

7:30 |

9:00 |

| FP4 PLUS |

3:30 |

4:10 |

| PANF |

Not recommended |

| Kodak 800 242-2424 |

| PAN-X |

4:40 |

5:40 |

| PLUS-X |

4:40 |

5:40 |

| TRI-X |

4:40 |

5:40 |

| TMAX 100 |

5:30 |

6:35 |

| TMAX 400 |

5:30 |

6:35 |

| Select TMAX |

3200 |

@85oF |

| TMAX 3200 @85oF |

5:45 |

6:55 |

If you want to change the developer time for one run, hold MINUS as you push START. The

display will show the developer time. Change to desired time using the PLUS and MINUS.

When the proper time is displayed push START to begin. The next time you process the unit

will return to the normal time.

As a rough guide, 1 stop is about:

a) + 2 min. for Slides E-6.

b) + 30 sec for color negs C-41.

c) + 20% of normal dev time for B/W

Call film manufacturer for more complete information.

Back

4 X 5 INSTRUCTIONS (optional)

Practice loading the 4x5 HOLDER with the lights on. The HOLDER will process 4 sheets at

a time.

The 2 stainless clips are on the TOP of HOLDER. Rotate both clips toward the center

core.

Insert the sheets with the emulsion towards the center. 4x5 sheet film has notches in

one corner. Hold the sheet facing you with the longer side vertical. When the notches are

at the top right corner, the emulsion is facing you.

Load the 2 inside sheets first. Load from the TOP of the HOLDER. Squeeze the film so

that it can fit inside the ring of the HOLDER. Push the sheet into the groove. Use your

other hand to help guide the sheets.

After all the sheets have been loaded, rotate the stainless clips toward the outside

ring to hold in the sheets.

The spindle should then be inserted from the bottom of the HOLDER. Place the spindle

with the HOLDER(S) in the Processing DRUM and process normally. Select DRUM SIZE = 4 for 1

HOLDER in the 4-roll DRUM and DRUM SIZE = 6 for 2 HOLDERS in the 8-roll DRUM.

After processing:

1. Remove the HOLDER(S) from the spindle.

2. Rotate the stainless clips toward the center core of the HOLDER

3. Push the sheet up slightly from the bottom.

4. Pull the sheet from the TOP. Use your other hand to help guide the sheet.

5. Use your own method to dry the sheets.

6. Rinse the HOLDER(S), spindle and DRUM. AIR DRY. DO NOT USE HOT AIR.

Very thin base 4x5 film like Kodalith will not mount in the holder.

AUTOMATIC REPLENISHING

Initially set up your unit to run without automatic replenishment. When you are

familiar with the operation and satisfied with the results, start using the replenishment

option.

Super Sidekick model SSK-8R can replenish any 2 chemicals, usually bleach and fix for a

great reduction in chemical costs. You get the highest quality results, because the

developers are fresh.

Replenishment is turned on when 3 conditions are met:

- The solution is saved as either bleach or fix. Save only one of each when you are

replenishing.

- The SAVE switch on the back of the SSK is turned on (red showing).

- The percentage of replenishment as set in PROGRAM MODE is not zero. See PROGRAM MODE.

Start with 9% bleach and 30% fix replenishment.

Replenishers are connected like any other solution: bleach to tube #7 and fix to tube

#12.

The SAVED solution drains to a HOLDING bottle, next time SSK uses that solution it will

pump up the set percent of replenisher and then pump up the used solution. When the

solution is used again, it drains back to the HOLDING bottle.

Because of the added replenisher, the volume in the HOLDING bottle increases. You have

to arrange the bottle so that the overflow flows away or is emptied manually.

The RETURN tubes are connected to the SAVE FIX and SAVE BLEACH tubes on the back of

Super SIDEKICK.

Connect the HOLDING bottle as per drawing:

1. The RETURN tubing must follow all the rules of a DUMP line.

a. Keep it short and going down as quickly as possible.

b. Minimum of a 12" drop.

c. End of tubing must never be in solution.

2. Allow 2 feet of slack on USED tubing.

3. Aerate the bleach with a fish tank air pump (2 hours/day or more) through the air

fitting. Do not use an airstone.

- The OVERFLOW should be directed to your container.

- Use black ¼" tubing to reach the bottom of the HOLDING tank for USED and Air.

Monitor your process results. If the film does not clear (milky) increase the fix

replenishment rate. You can usually re-fix the film manually to correct the problem.

If the film looks flat, muddy or the black areas have a red tinge, increase the bleach

replenishment rate and/or make sure the bleach is aerated. You can usually re-bleach the

film to correct the problem.

SERVICE

CORRECTING PROBLEMS

| Will not start up or gets stuck in process

step. Alarm does not sound |

Selector Valve jammed. Record display

messages. Remove DRUM, drain solution and put DRUM in bucket of water to protect the film.

Unplug & open unit and check ribbon connector and tubing to Selector (Rotary)

Valve. |

| Excessive leakage from front of DRUM, where

spindle passes through |

1.Improper draining. Reread how to run DUMP

lines. Run DUMP LINE TEST in TEST MODE. 2.The STAPLE is touching the spindle bushing

while the spindle is being pulled in. Adjust by mounting the STAPLE closer to the motor. |

| "Machine failure" message |

Temperature sensor problem. Check ribbon

connector from heat tank. Make sure it is pushed down, properly aligned and pins are

straight. Handle carefully. Lift up squarely. Do not just pull ribbon. If program

module was just replaced check it for bent pins

. |

| Film too dark or light |

1.Temperature off. See "Calibrate Temp" 2.Chemical

quality, mixing or age. |

| Film color off |

Chemical quality, mixing or age. |

| DRUM not recognized |

Clean contact plates on PROCESS DRUM. Run

sensor test. |

| Dev time counting down when STARTed |

DRUM sensor shorted. Replace DRUM. |

| Leak from snout. |

Grease "O" ring on DRUM snout. |

Use a telephone near Sidekick when calling in for service.

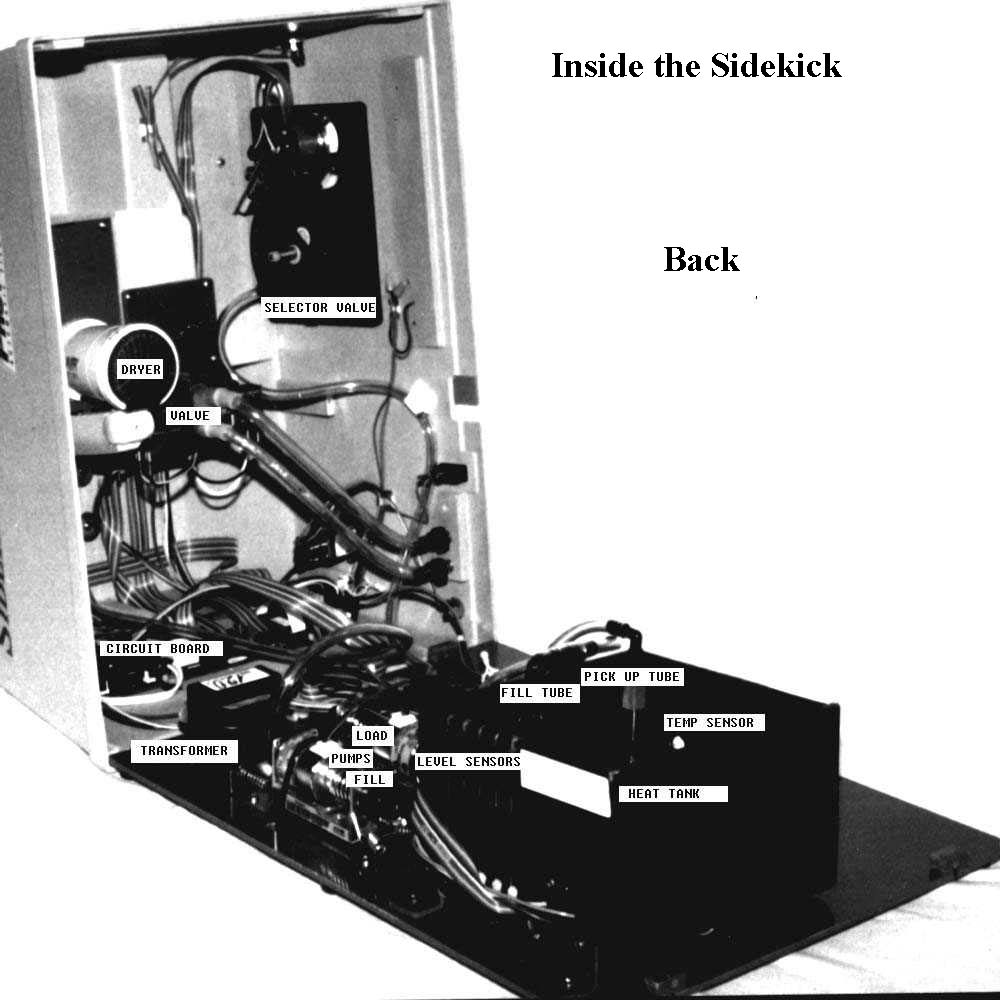

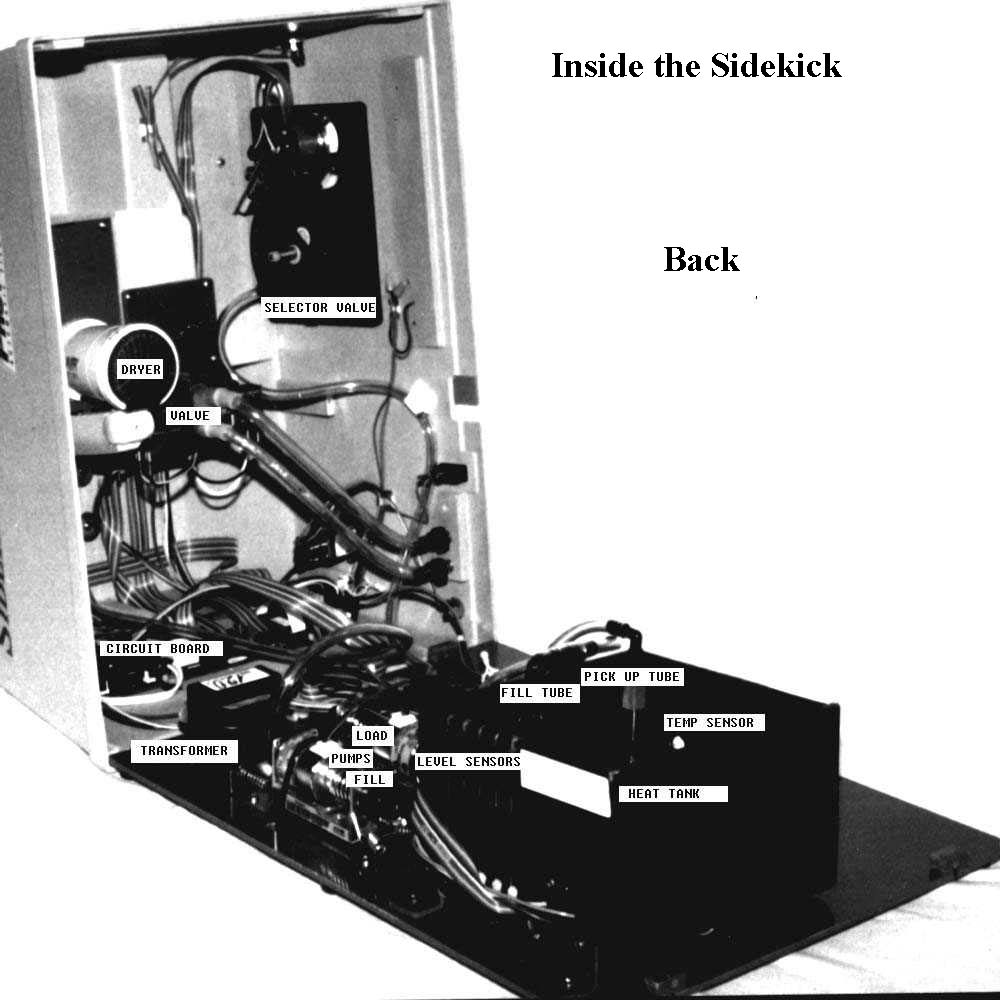

OPENING the UNIT. Qualified Personnel only

The unit must be opened in order to reach the internal components.

1) Remove the power cord from the unit and pull at least one battery from the battery

holder. Remove all the solution tubing from the tubes on the back of the unit.

2) Unscrew the 4 screws holding the BODY to the base (2 on the right side and 2 on the

left side). Lift up on the right side of the BODY so that it hinges on the left side. Rest

the BODY on its left side.

Back

Parts Replacement

SELECTOR VALVE REPLACEMENT

Open the unit (see OPENING). Cover the PC Board with paper towels and a plastic sheet

to protect it from getting wet. The SELECTOR VALVE (SV) is now exposed. The tubing from

the SV is held against the side of the case by a clamp. Open the clamp. With a paper towel

in hand; remove the SV tubing from the pump fitting.

Remove the ribbon connector of the SV from the PC board. Carefully lift the connector

straight up. Do not bend the pins. The SV is held with 4 screws. Unscrew and remove SV.

Carefully turn the SV so that it lines up on tube #9. Install the new SV. Fasten with

the 4 screws. Clamp the tubing to the case. The black mark on the tubing should line up

with the bottom of the clamp block. Push the end of the tubing onto the pump.

Remove the protective socket from the connector of the new SV and place it on the old

SV connector. Replace the electrical connector in the socket marked SELECTOR VALVE on the

PC board. The mark on the connector should be on the lower left corner.

Close up the unit. Do a test processing run.

PRINTED CIRCUIT (PC) BOARD REPLACEMENT

Open the unit (see OPENING). Locate the circuit board. Carefully note how each

connector is mounted before you pull it from the board. Pull away squarely from the board,

be careful not to bend the pins. Do not just yank the ribbon cables. Rotate the 2 clamps

holding the PC board and remove it.

Push the new PC against the stop on the right side of the track and then twist the

clamps. Carefully replace all the connectors. Use the wiring diagram (p.16) as a guide for

positioning. Close the unit and run CALIBRATE (see SPECIAL FUNCTIONS).

TEMPERATURE SENSOR REPLACEMENT

Open the unit (see OPENING). Locate the heating tank. The temperature sensor screws

into the side of the heating tank. There are 2 wires connecting the sensor. One goes to a

solder lug, and the other is soldered to a black wire. Cut away both wires (the wires are

interchangeable).

Wrap the new sensor with 4 wraps of Teflon tape and screw into the heat tank. Solder

the 2 wires where you cut the old wires. Close the unit and run CALIBRATE (see SPECIAL

FUNCTIONS) to match the sensor to the PC board.

SOLUTION LEVEL SETTING

Open the unit (see OPENING). Locate the 5 level sensors on the heat tank. The sensor

closest to the left corner is low level (4 oz -120 ml) followed by: 9 oz, 15 oz, 22 oz and

29 oz. Pour the proper amount of water (start with 4 oz then add 5 oz etc.) into the heat

tank. Hold the sensor where it passes over the tank wall with one hand and bend the end of

the sensor with the other hand so that the sensor just touches the water. Empty the heat

tank by closing the unit and running DRAIN (see SPECIAL FUNCTIONS).

SHIPPING the UNIT

Prepare the unit by running CLEAN LINES (see SPECIAL FUNCTIONS). Open the unit (see

OPENING) and wipe up any loose solutions. Tie down the 2 pumps (through the holes in the

base) with strong twine. Remove the magnetic stirrer (white pill) from inside the heat

chamber. Close the unit. Remove and keep stir bar, plug and power cord.

Place the unit in a plastic bag. Use as much packing (balled newspapers, bubble wrap

etc. <please do not use small Styrofoam chunks>) as possible to cushion the unit

from the walls of the box.

PARTS LIST SSK-8R Always specify model and serial number.

| SSK-SVR |

Selector Valve |

490.- |

AF-SPL |

Spindle 4-roll |

60.- |

| SK8-HT |

Heat tank |

350.- |

SK8-SPL |

Spindle 8-roll |

90.- |

| AF-TS |

Temperature sensor |

50.- |

SK8-D4 |

Process drum 4-roll |

140.- |

| SSK8-PC |

Printed circuit brd |

250.- |

SK8-D8 |

Process drum 8-roll |

160.- |

| AD-DISP |

Display |

90.- |

SSK-BOTH |

Holding bottle |

25.- |

| AF-TR |

Transformer |

75.- |

AF-BOT5 |

Bottle 5 Gal |

20.- |

| AD-P |

Pump |

140.- |

ADC-LEV |

Sensor for dump btl |

50.- |

| AF-DRT |

Dryer internal |

50.- |

AF-FV |

Float valve |

20.- |

| AF-DR8 |

Wall dryer 8 roll |

280.- |

AF-ICE |

Water connect kit |

15.- |

| AF-V3 |

Valve triple |

180.- |

AF-BOT2L |

Bottle 2 liter |

5.- |

| AF-VCL |

Valve coil 120V |

25.- |

AF-REEL |

Film reels Paterson |

10.- |

| AF-VST |

Valve seat |

5.- |

AF-LNCRD |

Power cord |

10.- |

| SSK-ROT |

Rotate motor |

105.- |

DP-SW |

Switch power. 2 pole |

7.- |

| AF-STAP |

Staple bushing |

10.- |

DP-PSW |

Push switch |

5.- |

| AF-STSL |

Staple sleeve (2) |

1.- |

AF-SW |

Switch save |

3.- |

| AF-4X5 |

4x5 holder |

90.- |

AF-BOT1G |

Bottle 1 gal (4 l) |

7.- |

| AF-C120 |

120 film clamps (3) |

2.- |

AF-OR |

"O" ring (3) |

2.- |

SUPPLIER PHONES

| 609 396-1456 |

Our help line. First check

CORRECTING PROBLEMS |

| 800 221 1555 |

Russell. 7-step Slide Chemistry.

Very helpful |

| 800 243-2776 |

Agfa |

| 800 788-3854 |

Fuji |

| 201 265-6000 |

Ilford |

| 800 242-2424 |

Kodak |

| 800 999-4042 |

PSI. Makes Unicolor 4-step slide

chemistry |

| 800 525-2821 |

Jobo. Imports Tetanol (Germany)

4-step slide chemistry |

| 800 621-5488 |

Brandess Kalt. Sell Heico Perma

Wash fix (hypo) remover |

| 800 553-2001 |

Porters. Get catalog. Has Rexton

Hyperwet #35-0597, a B/W rinse |

| 708 833-0300 |

McMasters. Ask for catalog. Has

silicone grease #1418K4 |

| 800 537-9724 |

United Plastics. Ask for catalog.

Good source for bottles, tubing etc. |

| 800 537-9724 |

Good stand for unit. Rubbermaid

4505. United Plastics # 06998 |

| 202 223-6906 |

Interclone. Profit-making slide

copier |

| 800 255-1522 |

Pic-Mount. Slide Mounters, mounts

and boxes |

| 612 936-9500 |

Pakon. Slide mounters and mounts. |

| 716 377-6375 |

Gepe. Snappy slide mounter. Slide

mounts for Snappy mounter |

| 800 309-4239 |

CDW. Tritt Lite. BC PRO 1400

Uninterruptable Power Supply |

Back

Push, Pull

Calculations

| Film speed |

Film Shot at |

Push |

Pull |

| 100 |

200 |

1 |

|

| 100 |

400 |

2 |

|

| 100 |

800 |

3 |

|

| 100 |

1600 |

4 |

|

| 200 |

400 |

1 |

|

| 200 |

800 |

2 |

|

| 200 |

1600 |

3 |

|

| 200 |

3200 |

4 |

|

| 400 |

800 |

1 |

|

| 400 |

1600 |

2 |

|

| 400 |

3200 |

3 |

|

| 800 |

1600 |

1 |

|

| 800 |

3200 |

2 |

|

| 1600 |

3200 |

1 |

|

| 3200 |

1600 |

|

1 |

| 3200 |

800 |

|

2 |

| 3200 |

400 |

|

3 |

| 3200 |

200 |

|

4 |

| 3200 |

100 |

|

5 |

| 1600 |

800 |

|

1 |

| 1600 |

400 |

|

2 |

| 1600 |

200 |

|

3 |

| 1600 |

100 |

|

4 |

| 800 |

400 |

|

1 |

| 800 |

200 |

|

2 |

| 800 |

100 |

|

3 |

| 400 |

200 |

|

1 |

| 400 |

100 |

|

2 |

| 200 |

100 |

|

1 |

| Film Type |

Dev. Time |

Push/Pull 1 |

Push/Pull 2 |

Push/Pull 3 |

| APX25 |

4:15 minutes |

+/-1:00 min |

+/-2:00 min |

+/-3:00 min |

| APX100 |

4:15 minutes |

+/-1:00 min |

+/-2:00 min |

+/-3:00 min |

| AP400 |

4:50 minutes |

+/-0:55 min |

+/-1:50 min |

+/-2:45 min |

| Neopan SS |

4:15 minutes |

+/-1:00 min |

+/-2:00 min |

+/-3:00 min |

| Neopan 400 |

4:40 minutes |

+/-1:10 min |

+/-2:20 min |

+/-3:30 min |

| Neopan 1600 |

3:30 minutes |

+/-1:10 min |

+/-2:20 min |

+/-3:30 min |

| HP5 Plus |

4:30 minutes |

+/-1:00 min |

+/-2:00 min |

+/-3:00 min |

| 100 Delta |

4:30 minutes |

+/-1:00 min |

+/- 2:00 min |

+/-3:00 min |

| 400 Delta |

5:00 minutes |

+/-1:00 min |

+/-2:00 min |

+/-3:00 min |

| SFX |

6:00 minutes |

+/-1:10 min |

+/-2:20 min |

+/-3:30 min |

| Universal 400 |

5:00 minutes |

+/-1:00 min |

+/-2:00 min |

+/-3:00 min |

| FP4 Plus |

3:30 minutes |

+/-0:40 min |

+/-1:20 min |

+/-2:00 min |

| Pan-X |

4:40 minutes |

+/-1:00 min |

+/-2:00 min |

+/- 3:00 min |

| Plus-X |

4:40 minutes |

+/-1:00 min |

+/-2:00 min |

+/-3:00 min |

| Tri-X |

4:40 minutes |

+/-1:00 min |

+/-2:00 min |

+/-3:00 min |

| Tmax 100 |

5:30 minutes |

+/-1:05 min |

+/-2:10 min |

+/-3:15 min |

| Tmax 400 |

5:50 minutes |

+/-1:05 min |

+/-2:10 min |

+/-3:15 min |

| Cosmos |

5:00 minutes |

+/-1:00 min |

+/-2:00 min |

+/-3:00 min |

| Tmax 3200 |

5:45 minutes |

+/-1:10 min |

+/-2:20 min |

+/-3:30 min |

Back

Black and White Developing Times

| Film |

Time |

| Agfa 201 440-2500 |

| APX 25 |

4:15 |

| APX 100 |

4:15 |

| AP 400 |

4:50 |

| Fuji 800 788-3854 |

| Neopan SS |

4:15 |

| Neopan 400 |

4:40 |

| Neopan 1600 |

3:30 |

| Ilford 201 265-6000 |

| HP5 PLUS |

4:30 |

| 100 DELTA |

4:30 |

| 400 DELTA |

5:00 |

| Delta 3200 |

7:30 |

| FP4 PLUS |

3:30 |

| PANF |

Not recommended |

| Kodak 800 242-2424 |

| PAN-X |

4:40 |

| PLUS-X |

4:40 |

| TRI-X |

4:40 |

| TMAX 100 |

5:30 |

| TMAX 400 |

5:30 |

| Select TMAX |

3200 |

| TMAX 3200 @85oF |

5:45 |

Back

First Frames

Not Developed

First turn your unit on leaving the drum off

and press the start button. If it starts, let the unit load the water up and see which

sensor in the heating chamber it stops. If it stops at the middle sensor, the two roll

drum sensor is bad and must be changed. If its the third, then its the four roll drum

sensor.

If the unit beeps and displays "insert proc drum", check your level

sensors for correct settings.Working from left to right, add 3oz of water to the heating

chamber.Make sure the tip of the first sensor is just touching the surface of the

water.Add 4 more oz of water, giving you 7 oz's and adjust the middle sensor. Now add 7

more oz of water giving you 14 oz's and adjust the third.If good, check to see if your

heating chamber empties out when fill the processing drum.. Third, try taking your largest

drum, no lid or spindle, insert it in the unit and add water. Let sit for 10 minutes. If

the level drops in the drum you will have to remove the valve assembly. Chances are there

is a piece of film stuck in there causing the valve to remain open during the process

It is located on the inside of the unit and in the middle. You can identify it by

its blue body and the two or three solenoids that is attached to it. if its two solenoids,

the wires will be yellow and black on one side and white and black on the other.If it has

three, the wire colors are, Grey and black, yellow and black and white and black.

You can remove the valve assembly by removing the two screws that hold it in the

Grey rectangular plastic block. Cover the circuit board! Start by

removing the solenoid with the yellow and black wire.

If you find nothing on the rubber seal or in side the valve body, remove the other

solenoid and check there

Back

Back

Stuck in process,

Bubbles from Front of Drum

If the unit appears stuck in one

part of the process and you here a pump running and bubbles coming from the front of the

processing drum, the low level sensor is making contact to the steel base plate of the

heating chamber, causing the unit to think there is still solution in there. First remove

the door on the right side of the unit so you will be able to look inside the heating

chamber. Look at the sensor furthest away from you. Make sure it is not touching the

bottom and that the spinbar has not come loose and has wedged itself between the sensor

and the bottom. If the sensor is touching, readjust it to 3oz of water. If the spinbar is

the problem, take a pencil and give it a shove to the right side corner. There a magnet

will grab it and hold it place.

If the above two are alright:

Take a pencil and run it under

all the level sensors. If the pump stops and the process continues, there was something

like a hair or algae from reversal hanging on the first level sensor. After the process,

inspect the heating chamber and clean. Also if your running 7 step E6 chemistry, inspect

your reversal bottle for algae.

Back

Not Loading one of the Chemicals

First make sure there is enough

chemical in the bottle. If that is not the problem, then the selector valve is sticking

slightly and needs a few lube cycles run on it.

Turn the unit on, hold the plus

button until you reach "Lube". Press the start button. Wait until the unit beeps

and tells you to "turn off unit".

Take the allen wrench that came

with the unit and insert it into the grease fitting in the back of the unit. Looking from

the front, it is above the last steel tube from the selector valve on the right. Give it

1/2 turn clockwise and turn the unit on until it Initializes.Repeat the

process again.

Back

Stuck in

"Flush"

This is the only function

the machine will not alarm if there is a problem.

First make sure you have

not run out of water or using deionized water. If there is plenty of water, look in the

heating chamber to see if there is water in it. If there is, see if there is water coming

out the flush line. If there is no water coming out the flush line and the heating chamber

has some water in it, turn the unit off then back on again and select drain. If the

heating chamber empties out, the load pump, the pump that draws the

solutions in the unit is failing. If it does not drain out, the fill

pump is failing

Back

Not Recognizing 4 Roll Drum-SK8

If the SK8 does not recognize the drum,

first clean the contacts on the machine and the drum. Gently push the contacts together on

the machine.

Insert the drum and try again. If the drum is

still not recognized, try inserting the other drum. If the machine operates properly, the

problem is with the one drum. Usually this means the sensor inside the drum has failed and

the drum needs to be replaced.

If neither drum is sensed by the machine, a

problem exists with one of the wires attached to the back of the contacts inside the

machine.

Open the unit and inspect each contact from the

inside.

On one contact you will find a red wire, and on

the other you will find a green.

Make sure both wires are tighten to the

contacts, and that they are not touching each other.

If all the above seems good, call the tech

support at Photo-Therm

Back

Only Half the

Roll Develops

If after processing you

find only half the roll was developed, find out first if the correct amount was selected

from the display, 2, 4, 6, or 8 and if the spacer was used if it was a 1, 2, 5, 6 roll

run.

If all the above was correct, check

your spindle for bent pins. When the pins on the spindle becomes bent in, it has a

tendency to push off the staple bushing during the process, leaving the spindle

stationary. When that happens, only the bottom half of the reel receives chemistry, giving

you a pattern of so many good frames, so many bad.

If the above two seem good,

insert the drum that was used, select the amount that was chosen, and start an E6 run. The

first solution that gets drawn up is water, so you wont be wasting chemistry.

On the right hand side of

the machine is a black door that you can remove and look inside the heating chamber. If

you selected 2 rolls, the water should stop at the second level sensor ( from left to

right ). If it was 4, it would be the middle sensor, 6 the forth sensor, and 8 the last.

If it stops at a different

sensor, there is a problem with either with the circuit board or the ribbon cable that

runs from the heating chamber. in this case, it's best to call PhotoTherm tech support,

(609) 396-1456.

If the water stops at the

correct sensor,

Take your largest drum, no lid

or spindle, insert it in the unit and add water. Let sit for 10 minutes. If the level

drops in the drum you will have to remove the valve assembly. Chances are there is a piece

of film stuck in there causing the valve to remain open during the process

It is located on the inside of the unit and in the middle. You

can identify it by its blue body and the two or three solenoids that is attached to it. if

its two solenoids, the wires will be yellow and black on one side and white and black on

the other.If it has three, the wire colors are, Grey and black, yellow and black and white

and black.

You can remove the valve assembly by removing the two screws that

hold it in the Grey rectangular plastic block. Cover the circuit board! Start

by removing the solenoid with the yellow and black wire.

If you find nothing on the rubber seal or in side the valve body,

remove the other solenoid and check there

Back

Processing drum

starts to count down

If after you insert the four or the eight roll processing

drum and press start the drum starts to count down on the display, the sensor inside the

drum has shorted and the drum must be replaced. If this happens on both drums, the

contactors on the machine my be making contact inside

Open the unit and

inspect each contact from the inside.

On one contact you will find a red wire, and on

the other you will find a green.

Make sure both wires are tighten to the

contacts, and that they are not touching each other.

Back

First Frames Not Developed SK8

If the first few frames are not getting

developed, there is not enough solution in the processing drum to reach the center of the

reel

Working from left to right, add 4oz of water to the heating chamber.Make sure

the tip of the first sensor is just touching the surface of the water.Add 5 more oz of

water, giving you 9 oz's and adjust the second sensor. Now add 6 more oz of water giving

you 15 oz's and adjust the third. Now add 7 more oz of water giving you 22oz of water and

adjust the forth then 7 more oz and and adjust the fifth. IF YOUR

FOUR ROLL DRUM IS THE NEWER STYLE WITH RED CLIPS HOLDING THE TOP TO THE DRUM, THEN THE

MEASUREMENTS ARE, 4oz, 7oz, 4oz, 7oz, 7oz.

If good, check to see if your heating chamber

empties out when fill the processing drum.. Third, try taking your largest drum, no lid or

spindle, insert it in the unit and add water. Let sit for 10 minutes. If the level drops

in the drum you will have to remove the valve assembly. Chances are there is a piece of

film stuck in there causing the valve to remain open during the

process

It is located on the inside of the unit and in the middle. You can identify it by

its blue body and the two or three solenoids that is attached to it. if its two solenoids,

the wires will be yellow and black on one side and white and black on the other.If it has

three, the wire colors are, Grey and black, yellow and black and white and black.

You can remove the valve assembly by removing the two screws that hold it in the

Grey rectangular plastic block. Cover the circuit board! Start by removing

the solenoid with the yellow and black wire.

If you find nothing on the rubber seal or in side the valve body, remove the

other solenoid and check there

Back

Machine will not

Draw up Chemicals

If the machine does not fill the heating

chamber, to the proper level, in a predetermined time, the unit will go into an alarm and

the display screen will indicate which chemical was unsuccessfully loaded.

First check the chemical bottle to make sure

there is an ample amount in the container. If OK, the problem is either the selector valve

or pump.

First, open the unit. Be sure to cover the

circuit board with a towel to keep from getting wet. Then locate the fill pump on the gray

base plate. It will be the pump closest to the center of the base plate. Remove the vinyl

tube that runs from the selector valve to the pump at the pump end. Attach your water line

(port 5) to the pump. Turn the machine on and select, "Calibrate Temp", press

start. If the pump, appears to be weak, you will need to order a new pump. If it appears

to work well, chances are the rotary selector valve is dirty and needs to be cleaned.

Remove the rotary selector valve and

disassemble it. With warm soapy water, carefully clean the face plate, (The area on which

the o rings travel against) DO NOT USE ANYTHING ABRASIVE AS IT WILL SCRATCH THE SURFACE!

Reassemble and run "Clean Lines" to

insure it is working well.

Unit

Diagram

Back

Only Half the Roll

Develops sk4

If after processing you

find only half the roll was developed, try

these test to determine where the problem is.

First turn your unit on leaving the drum

off and press the start button. If it starts, let the unit load the water up and see which

sensor in the heating chamber it stops. If it stops at the middle sensor, the two roll

drum sensor is bad and must be changed. If its the third, then its the four roll drum

sensor.

If the unit beeps and displays "insert proc drum", check your level

sensors for correct settings.Working from left to right, add 3oz of water to the heating

chamber.Make sure the tip of the first sensor is just touching the surface of the

water.Add 4 more oz of water, giving you 7 oz's and adjust the middle sensor. Now add 7